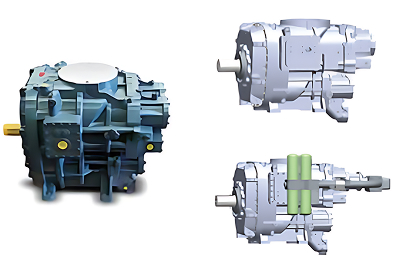

Two-stage Oil Injection Compressor

APH Series

High-Pressure Screw Compressor Features

-

Maximized Efficiency

Stable and consistent air pressure production without pulsation, unlike high-pressure piston compressors

-

Enhanced Mechanical Durability & Simplified Maintenance

High durability of bearings compared to high-pressure piston compressors, and simplified maintenance by integrating parts without piston ring replacement

-

Low Vibration, Low Noise Realization

Quieter operation compared to high-pressure piston compressors due to screw internal flow analysis design

High-Pressure Screw Compressor Application Areas

-

![[PET Container Industry]](https://lmeng.kr/midam/page/product/product2/cat1_1.jpg)

[PET Container Industry]

-

![[Petrochemical Refining Industry]](https://lmeng.kr/midam/page/product/product2/cat1_2.jpg)

[Petrochemical Refining Industry]

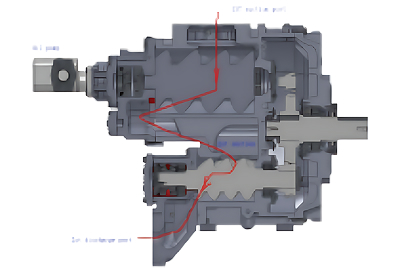

2-Stage High-Pressure Screw Air-End Features

-

Integrated structure with high-pressure oil filter and

lubrication pump components prevents oil loss and enhances

bearing/gear lubrication for fault prevention

(operable in various pressure ranges)Long mechanical life guaranteed by applying heavy-duty

bearings and SKF bearings -

Rotor profile structure optimized for high-pressure

air compressor applications

(Standard 4/5-lobe rotor combination,

High-pressure 5/6-lobe rotor combination)Multi-oil injection to improve intermediate cooling

efficiency between low and high pressure

(Especially inlet/outlet design method)

2-Stage High-Pressure Screw Air-End Internal View

2-Stage High-Pressure Screw Air-End Special Order Request

| Item | Model (8 Series / B-PUMP Added Model) |

Discharge Flow Range (㎥/min) |

|---|---|---|

| 1 | GE805 / GE805B | 4.76 ~ 7.23 |

| 2 | GE810 / GE810B | 6.98 ~ 14.80 |

| 3 | GE815 / GE815B | 11.15 ~ 18.52 |

| 4 | GE825 / GE825B | 15.98 ~ 24.56 |

| 5 | GE835 / GE835B | 21.33 ~ 35.12 |

| 6 | GE840 / GE840B | 30.53 ~ 55.02 |

8 Series Specification

Flow Rate: 4.76 ~ 55.02 ㎥/min

Discharge Pressure: 17.0 ~ 40.0 kgf/㎠

Purchase Inquiry

For specifications and purchase inquiries about high and low-pressure compressors, please contact our sales department.